“The overall total cost of ownership of that machine is going down substantially when you compare it to a conventional machine,” Gribble said. Gribble said that these systems help contractors extend the lives of their wheel loaders and avoid extra maintenance costs such as tire replacements and machine damage. The 644 X-Tier wheel loader comes with an E-Drive transmission system that delivers “premium performance and efficiency,” according to John Deere’s site, and the 944K model has a hybrid-electric drive that recaptures energy to slow the machine when the operator lets off the accelerator, a feature that lessens the load on the engine and reduces fuel consumption.

“It’s something that provides a lot of those benefits: more efficient, more productive, easier for the operator to us,” Gribble said. Luke Gribble, solutions marketing manager at John Deere, said the manufacturer’s hybrid-electric drive (or E-Drive) makes the company’s wheel loaders stand out, even though the technology has been operating with the 644 X-Tier mid-sized and 944K hybrid large models for a few years now. John Deere is modernizing its fleet of wheel loaders with its own efficiency measures. “That type of technology just helps make the machine more efficient, more productive, and at the end of the day, burns less fuel, and it makes the operator more productive they can meet their targets throughout the day,” Kleingartner said. He said the functionality’s job is to make minor adjustments when needed to reduce the hydraulic output – this makes sure the engine doesn’t bog down while staying within its prime working range.

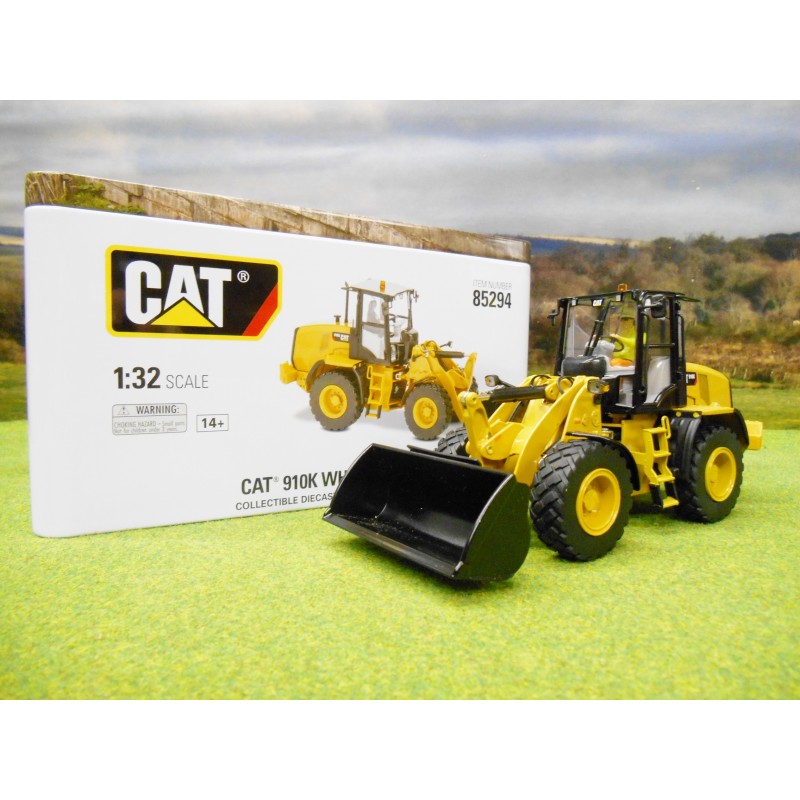

CAT LOADER MODELS SERIES

The result is what Doosan calls “situational awareness technology,” which was introduced with the -7 Series of wheel loaders, and it senses the speed, power and hydraulic needs of the machines, according to Kleingartner. That confidence in the wheel loader’s steady two-pass performance means it’s easier for jobsites to manage and maximize time, fuel, logistics and efficiency.Īn ongoing trend with equipment is the shift to more fuel-efficient machines with lower emissions, Kleingartner said, and Doosan’s engineers have been tasked with meeting various emissions regulations.Īlthough complying with those mandates is necessary, Kleingartner said that adding productivity features to their machines while ensuring they’re more fuel-efficient. “That true two-pass has been a great addition to our lineup, and the -7 Series machines, in general, are the next generation of the product.” “From the cycle-time perspective, can wreak havoc in a day having that extra half-load you sometimes end with overloaded trucks and underloaded trucks,” Kleingartner said. Several leading manufacturers have released new models, including the new G-Series from Case Caterpillar’s 980, 982 and 992 machines and Doosan Infracore North America’s D元80-7, which joined the company’s -7 Series of wheel loaders.ĬONEXPO-CON/AGG 365 talked with equipment OEMs to discover the upgrades that contractors can take advantage of today.ĭoosan debuted the DL-580-5 wheel loader, with an operating weight just under 80,000 lbs, at CONEXPO-CON/AGG in March 2020, and since then, the manufacturer has refreshed it and the models in its -7 Series.Īaron Kleingartner, product and dealer marketing manager for Doosan Infracore North America, said the 580-7, which has a bucket capacity of 8.4 cubic yards, is a “true two-pass machine,” which means it fills up trucks in two loads – not 2.5 loads like some smaller wheel loader models.

A staple on many job sites, the wheel loader has undergone several innovations in the past few years – and will see even further updates in the near future.

0 kommentar(er)

0 kommentar(er)